The grass brooms manufacturers have recently researched an electromagnetic broom. Here is a detailed introduction to how it works.

Product principle:

This product is manufactured by the principle of “electricity magnetism”. Electromagnetism, that is, when a current is passed through a wire, a circular “field” is formed around the wire, called a magnetic field. This magnetic field surrounds the wire and will increase as the current increases.

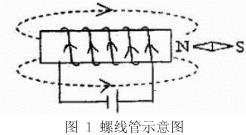

If a long wire is wound in a hollow “drum” in a certain direction, a solenoid is formed. If this solenoid is energized, then each of the wires above the solenoid will generate a magnetic field, as shown in Figure 1. At the position between the adjacent two turns, the total magnetic field cancels out due to the opposite direction of the magnetic field; therefore, the magnetic field generated by each turn of the wire is superimposed inside and outside the solenoid, eventually forming a magnetic field as shown in FIG. shape. The magnetic fields inside and outside the solenoid are superimposed to form a closed magnetic field.

When current is passed through the wire, a magnetic field is created around the wire. According to this characteristic, if a current is passed through the solenoid, a magnetic field of a certain intensity is formed around the solenoid. Assuming that a core is placed in the solenoid, the core is magnetized and the magnetic field strength of the solenoid is greatly enhanced.

According to the classification, magnets can be divided into “permanent magnets” and “non-permanent magnets”. The permanent magnets may be naturally formed magnets or may be made manually. Non-permanent magnets are generally manufactured by hand, such as electromagnets. They need to add some specific conditions in order to be “magnetic.”

Electromagnets can be divided into DC electromagnets and AC electromagnets. Electromagnets are used in a wide range of applications because of their unique advantages. The electromagnet can control the magnetic oil pollution by the on and off of the current == presence or absence; it can also control the magnetic size by the magnitude of the current; it can also control the magnetic pole direction by the direction of the current.

This product is the advantage of using electromagnets. When there is current, the electromagnet is magnetic and attracts iron scraps. When there is no current, the electromagnet loses its magnetism and “puts down” the iron scraps to realize the function of iron scrap recovery.

Product structure and design

This product is generally made of PVC material, designed according to the ergonomic principle, the power supply uses 220V AC power.

This versatile electromagnetic broom is divided into three main sections.

Hand lever: There is a hook at the top of the hand lever. This hook can be hung on the wall, with the middle of the hand on the upper side. There are two switches, one for controlling the white LED light and the other for controlling the closing of the electromagnet. The hand lever is divided into two sections, which are flexible and controllable.

Electromagnet: The electromagnet uses AC power. It is enclosed in a plastic case of PVC. Two LED white lights are installed outside the PVC plastic case for easy illumination.

Broom wire: The broom wire is made of PET plastic and is easy to absorb iron filings. The specific structure of the product is shown in Figure 2.

-300x166.jpg)

Product advantages and application places

At present, electromagnetic brushes have been introduced on the market, and it has its own advantages, which can remove iron filings from employees. However, the area of the electromagnetic brush is too small, and if it can be combined with an electromagnetic broom, the garbage waste of the factory can be classified and recovered.

This product is mainly used for large enterprises, factories, scientific research sites and other places where iron filings, screws, and nails are prone to occur, which can improve recycling efficiency.